Alliant Castings provides a wide range of casting materials that are iron alloys, including custom alloys to meet specific customer needs. Our alloys fall into five broad families:

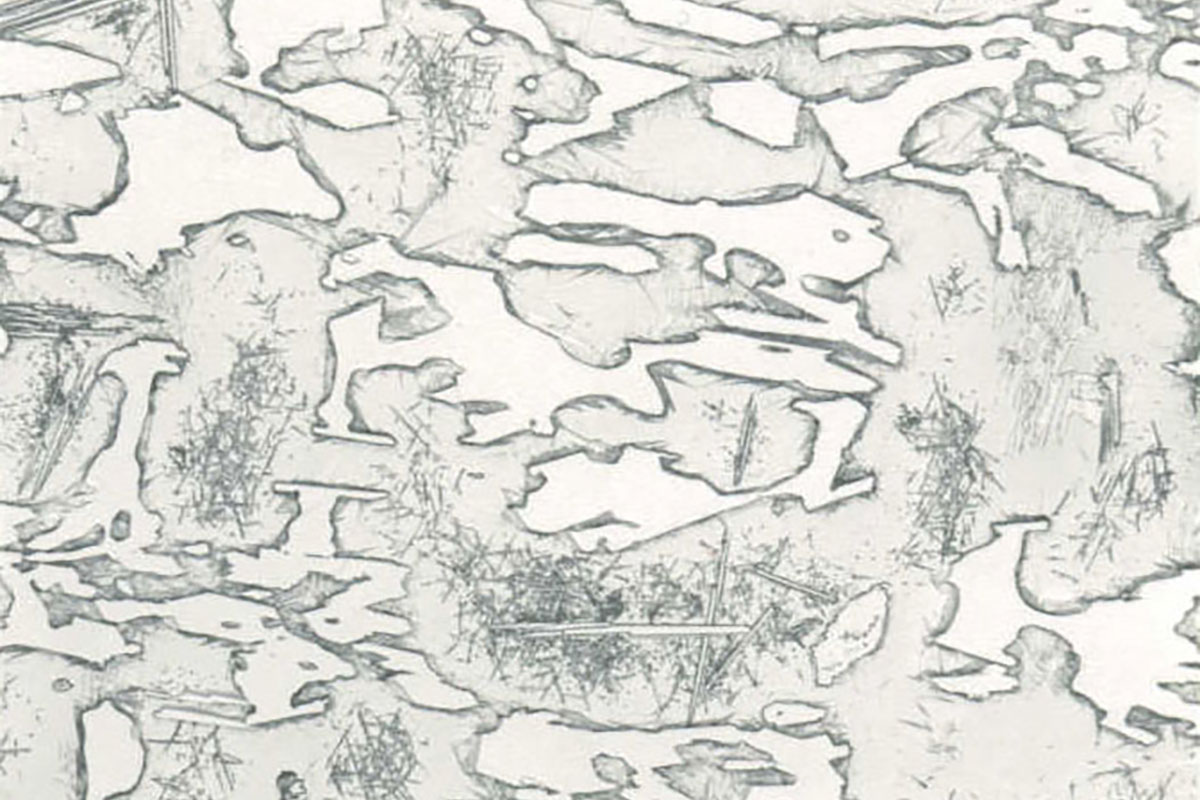

NiHard Family

NiHard Family, developed in the 1920’s to increase the market for nickel, Nihard uses nickel and chromium in cast iron to produce a wear resistant microstructure. Typically, Nihard is used in sliding abrasion application where there is limited impact.

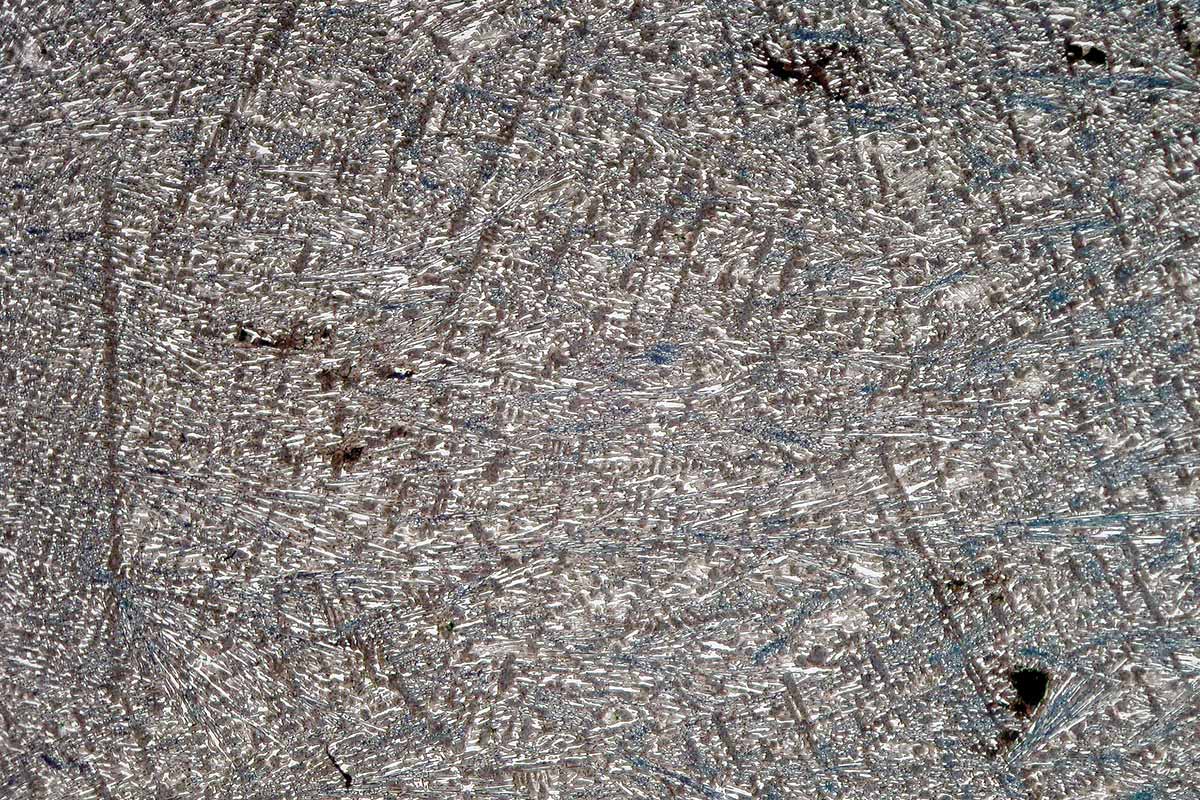

High Chrome Family

High Chrome Family, developed around 1915 in anticipation of alloy shortages due to WW1. This family of alloys utilizes chromium levels ranging from 15-28%. The combination of carbon and chromium develop chromium carbides in the wear resistant mircrostructure. Chrome Iron provides better impact resistance and abrasion resistance, often at little extra cost. Within the high chrome family we are especially proud of AC800, a proprietary alloy that marries Hi Chrome chemistry with optimum heat treatment to provide an exceptional level of abrasion resistance.

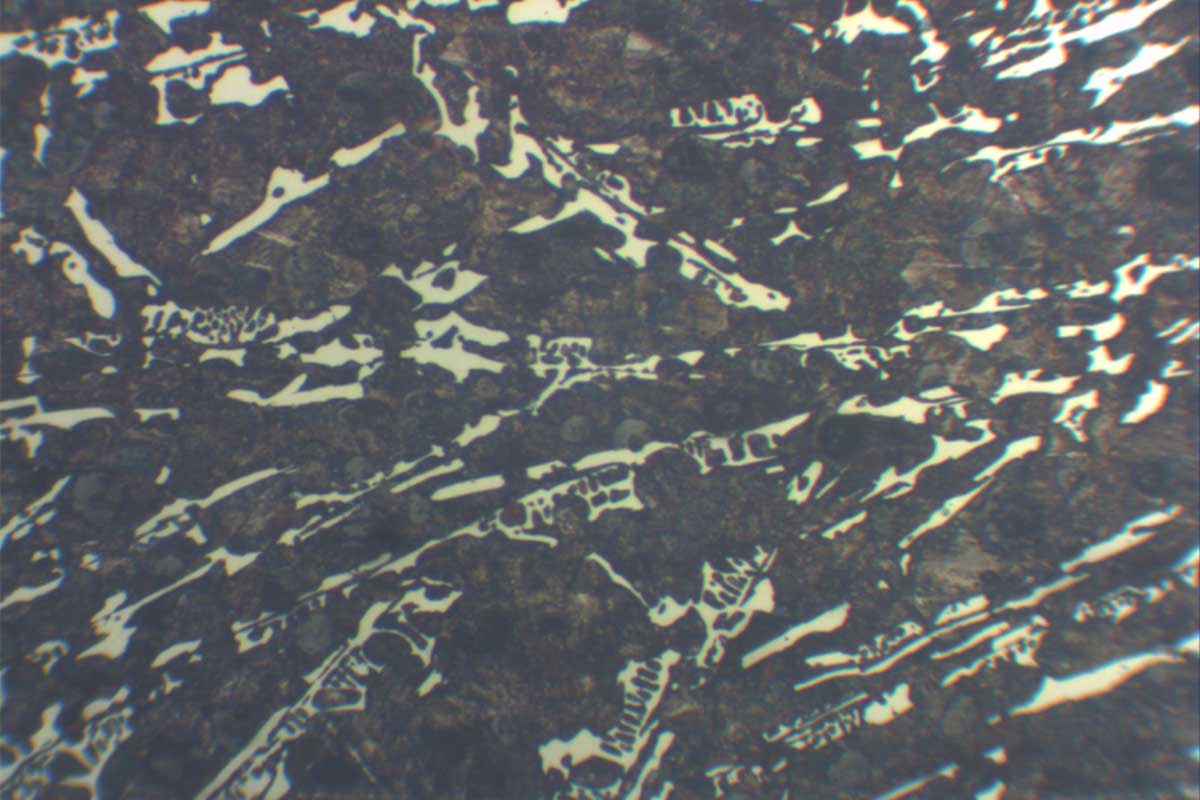

Carbidic Austempered Ductile Iron (CADI) Family

Carbidic Austempered Ductile Iron (CADI) Family combines the toughness of ductile iron as well wear resistance found in abrasion resistant irons. CADI is a material that uses a matrix of ausferrite, carbides and nodular graphite to add strength and wear resistance. The result is an alternative to conventional steel and iron parts.

Ni-Resist Austenitic Cast Iron Alloys

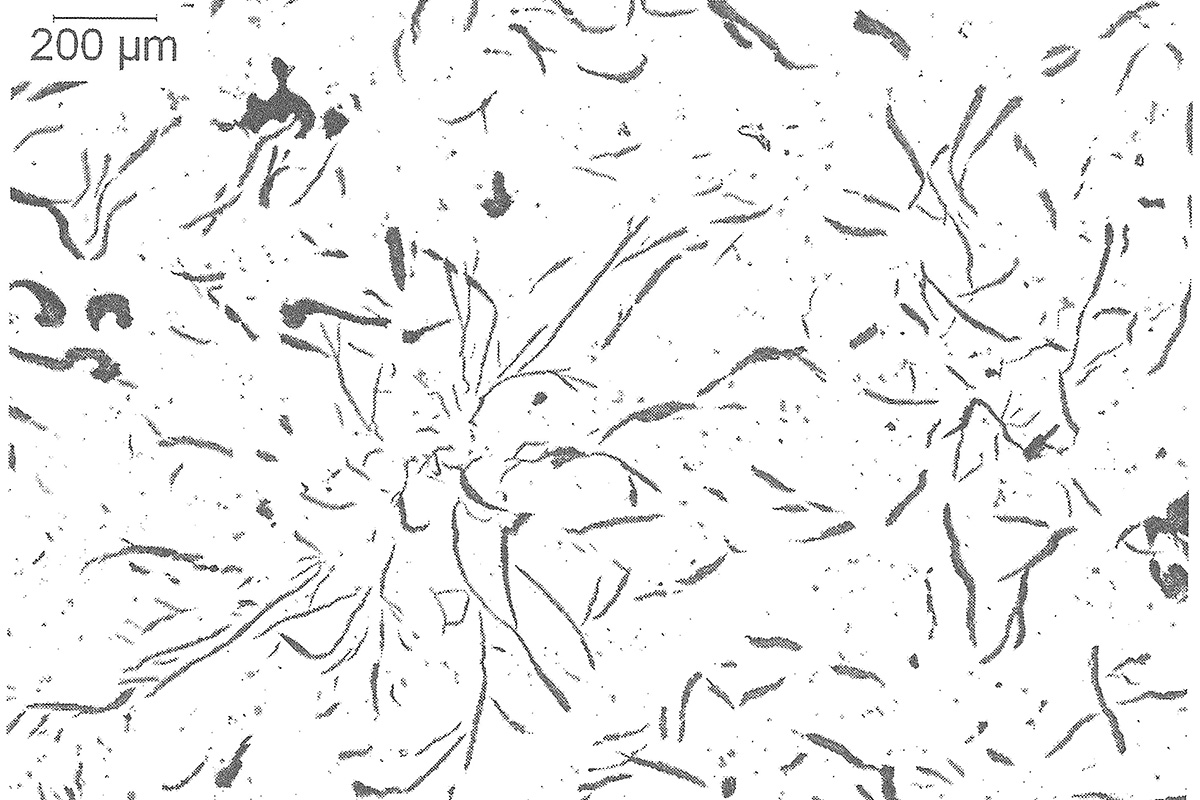

There are two families of Ni-Resist austenitic cast irons. These are the standard or flake graphite alloys and the ductile or spheroidal graphite alloys. Because of their higher strength, ductile grades are gaining more prominence. However, flake graphite Ni-Resists have a lower cost, fewer casting problems and better machinability and are still produced today. Both flake and spheroidal graphite grades are used in corrosive, wear-resistant, and low-temperature environments.

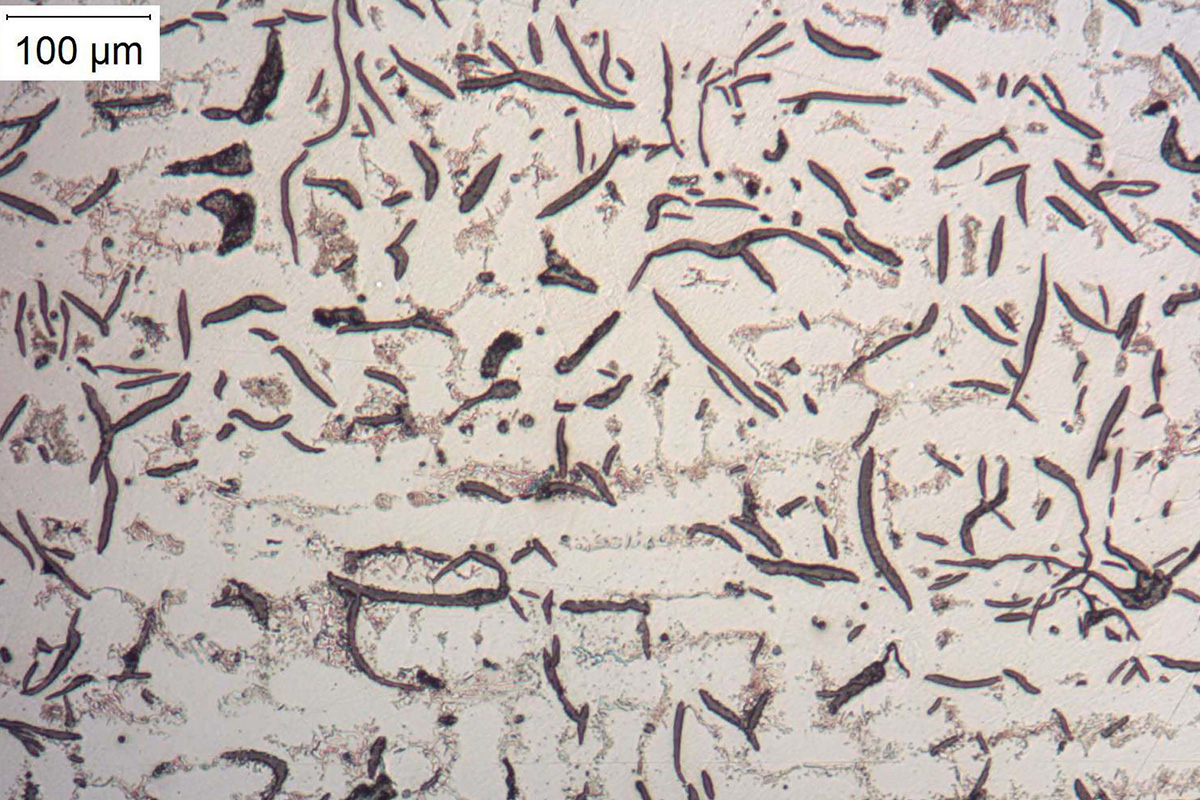

Gray Cast Iron Alloys

A widely used family of irons. Examination of a gray iron fracture surface, it’s gray in color. Hence, the name “gray iron”. Gray irons have excellent machinability, good wear resistance and ability to absorb vibration. Typically classed based on tensile strength. For example, a “Class 30” gray iron has a 30,000-psi ultimate tensile strength.

Our metallurgist is available to discuss your alloy requirements of your parts.